Mine site Operation

Sand Particle Info

Sand Particle Info

Albany Silica Sand is high purity silica sand with a round shape. This sand can meet a wide range of size requirements from coarse sand to fine sand by the sizing process plant with our original process technology. This sand is recently being spotlighted as the best material sand with super-low iron content for high quality glass fields such as solar Continue Reading...

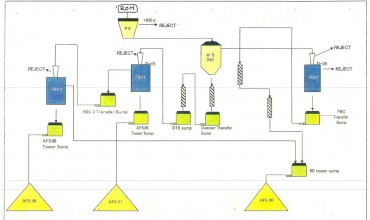

Albany Production Flow Chart

Albany Production Flow Chart

Click image to view the flow chart....

Overview of Mine Site Operation

Austsand Mining’s mine site is situated approx 45kms Nth East of Albany in the Manypeaks region, and covers a lease area of 260 hectares of natural vegetation.

The mine operates under licence from Department of Environment Regulation, and conditions imposed under Department of Mines and Petroleum, Mining Lease 70/793.

The mine site is a 24hr, 4 day a week operation, depending on production targets, this can be increased.

The mining process consists of, removal and storage of vegetation from planned mining areas, topsoil is then removed, and respread on the previously mined and reshaped areas, this has shown to greatly improve the quality of rehabilitation, and ensures natural vegetation is re-established.

Front end loaders mine the ore material to a depth of approx 6 mtrs, this material is processed through a movable in pit screening unit, to remove + 850µ material, ie,rocks,clay or large impurities.

The retained product from the screening unit is mixed with process water and pumped approx 800mtrs to the top floor of the process classifying plant for further treatment.

The process classifying plant consists of a series of pumps, sumps, hydraulic classifiers and wet spiral concentrators, and dewatering cyclones.

Material is pumped through a number of hydraulic classifiers to produce the required size ranges of final products to meet customer demand, product is then gravity fed through spiral concentrators to remove any remnant heavy metals.

The final product is then de–watered via cyclones, to separate stockpile areas according to grade, where it is stockpiled, and awaiting transport via road train to the port facility ready for shipping.

Emphasis is on a quality product, therefore on going sampling throughout the shifts, maintains quality control on the final products.

Tailings material and excess water from the classifying plant is pumped to a tailings dam where the water is recovered for reuse.

3 front end loaders and a 40 ton articulated dump truck are used on site –

1 x loader and dump truck are used to transport the raw feed from the mining area to the primary screen.

The 2nd loader is feeding the raw feed into the ROM hopper for processing.

The 3rd loader is managing the final product stockpiles and loading product onto road trains for transport to the port facility.

There are approximately 10 personnel on site (4 Staff and 6 x labour hire operators) while contractors carry out the transport of the product to the port, and electrical and mechanical maintenance.